|

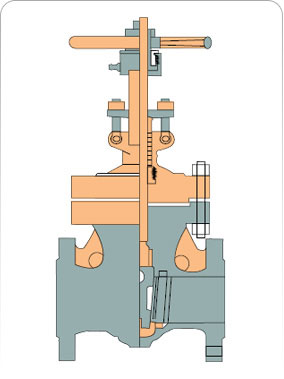

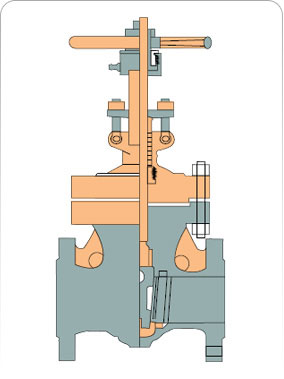

Body and Bonnet |

|

|

Castings are precisely machined. The gasket contacting surface is smooth finish that has a roughness between Ra 3.2 and 6.3 micrometer (125-250microinch). The surface roughness of gasket grooves of ring joint faces do not exceed 63 micro inch. Body seat construction of cast steel Gate Valves has three types: threaded seat ring, welded seat ring and integral seat ring. Provided with bosses for optional by-passes or drains.

|

| |

|

Stem |

|

|

Non-rotating stem with precision Acme threads and burnished finish. Double Acme for faster operation. All wedge gate valves are provided with upset forged T-head stems. 16 to 32 RMS stem surface finish, straightness and roundness are precisely controlled according to design and manufacturing standards.

|

| |

|

Stuffing Box |

|

|

Maximum 125 RMS surface finish. Cylindricity and verticality are precisely controlled according to design and manufacturing standards. Optional lantern rings and grease injectors are available.

|

| |

|

Gland and Packing |

|

|

Gland has a two-piece construction for easy alignment. Middle rings die formed 100% laminated flexible graphite rings, top and bottom rings lattice braided graphite fiber with corrosion inhibitor.

|

| |

|

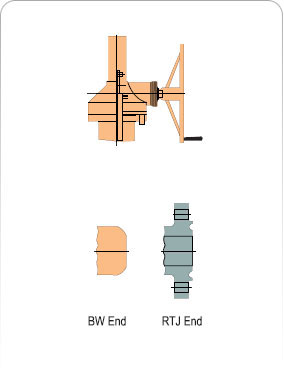

Bonnet Gasket |

|

|

Class 150: Jacketed graphite with stainless steel. Class 300 Class 600 : Jacketed graphite with stainless steel or Spiral wound graphite with stainless steel. Class 900 and over: Ring joint metal gasket.

|

| |

|

Bonnet Bolting |

|

| Coarse thread series for bolt sizes 1 inch and smaller,8-thread series for bolt sizes 11/8 inch and larger, both conform to Class 2A/2B tolerances. |

| |

|

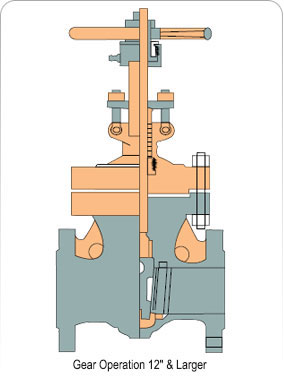

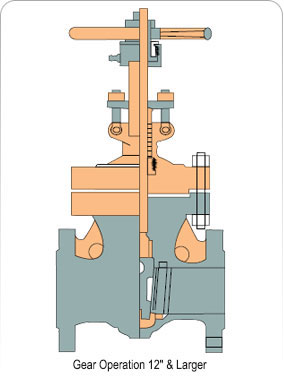

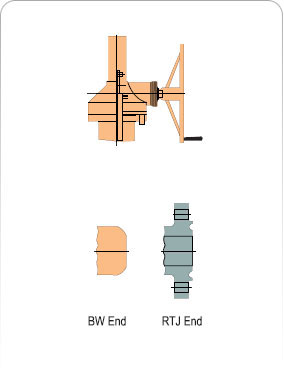

Operators |

|

|

Gate valve normally are to be supplied to complete with the suitable hand wheel. An available with gear, electric motor actuators, or cylinder actuators for remote operation. All valve with hand-wheels operator, including those on gear operators, be marked "open" or "close" with an arrow indicating the direction of rotation. Under maximum differential pressure, maximum allowable Rim Pull is 350N.

|

| Salient Features |

|

|

|

|

| TEST PRESSURE-PSI |

| Hydrostatic |

Class 150 |

Class 300 |

Class 400 |

Class 600 |

Class 900 |

Class 1500 |

Class 2500 |

| Body |

450 |

1122 |

1450 |

2175 |

3250 |

5400 |

9000 |

| Seat |

315 |

825 |

1060 |

1600 |

2400 |

4000 |

6000 |

|

| |

| Notes for Gate Valve |

|

|

|

| Parts List |

| No. |

Parts |

Material |

| 01 |

Body |

ASTM A216 Gr.WCB |

| 02 |

Seat Ring |

Attached |

| 03 |

Wedge |

ASTMA216WCB+13Cr |

| 04 |

Stem |

S.S. 410 |

| 05 |

Gasket |

Spiral wound SS 304 CAF/ Graphite |

| 06 |

Bonnet Bolt |

ASTM A193 Gr.B7 |

| 07 |

Bonnet Nut |

ASTM A194 Gr.2H |

| 08 |

Bonnet |

ASTM A216 Gr.WCB |

| 09 |

Backseat |

ASTM A276 410 |

| 10 |

Packing |

Graphite |

| 11 |

Pin |

C.S. |

| 12 |

Gland Bolt |

ASTM A193 Gr.B7 |

| 13 |

Gland Nut |

ASTM A194 Gr.2H |

| 14 |

Gland |

M.S. Proplyn |

| 15 |

Gland Flange |

ASTM A216 Gr.WCB |

| 16 |

Stem Nut |

M.S. |

| 17 |

Retaining Nut |

M.S. |

| 18 |

Handwheel |

S.G. Iron |

| 19 |

H.W. Lock Nut |

M.S. |

| 20 |

Lubricator |

Assem. |

|

|

| Applicable Standards |

| |

API |

BS |

DIN |

| PRESSURE TEMPERATURE |

ANSI-B 16.5 |

1560 |

2401 |

| RATING |

ANSI-B 16.34 |

- |

- |

| END TO END DIMENSION |

ANSI-B 16.10 |

2080 |

3202 |

| FLANGES |

ANSI-B 16.5 |

1560 |

2543 |

| B W ENDS |

ANSI-B 16.25 |

- |

2544 |

| |

- |

- |

2545 |

| INSPECTION & TESTING |

API -598 |

5146/ |

3230 |

| |

- |

6755 P.I. |

|

|

| |

| |

| Class 150 150# Gate Valve |

NOM.

SIZE |

40

mm |

50

mm |

65

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

400

mm |

| L |

165 |

178 |

191 |

203 |

229 |

254 |

267 |

292 |

330 |

365 |

406 |

| D |

127 |

152.4 |

177.8 |

190.5 |

229 |

254 |

279.4 |

342.9 |

406.4 |

482.6 |

591.9 |

| T |

17.5 |

19 |

22.2 |

23.8 |

23.8 |

23.8 |

25.4 |

28.6 |

30.2 |

31.7 |

36.7 |

| H |

340 |

368 |

418 |

441 |

514 |

578 |

660 |

826 |

991 |

1148 |

1341 |

| H1 |

378 |

419 |

492 |

518 |

616 |

705 |

812 |

1076 |

1076 |

1453 |

1743 |

|

| (All dimensions in mm) |

| Class 300 300# Gate Valve

|

NOM.

SIZE |

40

mm |

50

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

400

mm |

| L |

191 |

216 |

283 |

305 |

381 |

403 |

419 |

457 |

502 |

838 |

| D |

156 |

165 |

210 |

254 |

279.4 |

318 |

381 |

445 |

521 |

647.7 |

| T |

21 |

22 |

29 |

32 |

35 |

37 |

41 |

48 |

51 |

57.1 |

| H |

381 |

395 |

451 |

527 |

629 |

695 |

852 |

1023 |

1178 |

1387 |

| H1 |

419 |

446 |

531 |

629 |

756 |

847 |

1055 |

1277 |

1483 |

1794 |

|

| (All dimensions in mm) |

| Class 400 400# Gate Valve

|

NOM.

SIZE |

40

mm |

50

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

400

mm |

| L |

241 |

292 |

330 |

356 |

406 |

457 |

495 |

597 |

673 |

762 |

| D |

155.6 |

165.1 |

190.5 |

209.5 |

254 |

279.4 |

317.5 |

381 |

44.45 |

521 |

| T |

22.2 |

25.4 |

23.6 |

31.8 |

35 |

38.1 |

41.2 |

47.8 |

53.8 |

57.15 |

| H |

390 |

430 |

500 |

530 |

580 |

640 |

750 |

925 |

1080 |

1210 |

| H1 |

435 |

490 |

570 |

615 |

690 |

785 |

910 |

1138 |

1345 |

1525 |

|

| (All dimensions in mm) |

|

|

| Class 600 600# Gate Valve |

NOM.

SIZE |

40

mm |

50

mm |

65

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

| L |

241 |

292 |

330 |

356 |

432 |

508 |

559 |

660 |

787 |

838 |

| D |

155.6 |

165.1 |

190.5 |

209.5 |

273 |

330.2 |

355.6 |

419.1 |

508 |

558.8 |

| T |

22.2 |

25.4 |

28.6 |

31.7 |

38.1 |

44.4 |

47.6 |

55.6 |

63.5 |

66.7 |

| H |

412 |

480 |

500 |

581 |

658 |

686 |

845 |

1010 |

1165 |

1310 |

| H1 |

464 |

549 |

580 |

667 |

781 |

832 |

1015 |

1246 |

1427 |

1620 |

|

| (All dimensions in mm) |

| Class 900 900# Gate Valve

|

NOM.

SIZE |

40

mm |

50

mm |

65

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

| L |

305 |

368 |

419 |

381 |

457 |

559 |

610 |

737 |

838 |

965 |

| D |

177.8 |

215.9 |

244.5 |

241.3 |

292.1 |

349.2 |

381 |

469.9 |

546.1 |

609.6 |

| T |

31.7 |

38.1 |

41.3 |

38.1 |

44.4 |

50.8 |

55.6 |

63.5 |

69.8 |

79.4 |

| H |

520 |

550 |

605 |

615 |

760 |

810 |

950 |

1102 |

1248 |

1375 |

| H1 |

562 |

603 |

670 |

798 |

870 |

945 |

1110 |

1305 |

1501 |

1672 |

|

| (All dimensions in mm) |

| Class 1500 1500# Gate Valve

|

NOM.

SIZE |

40

mm |

50

mm |

65

mm |

80

mm |

100

mm |

125

mm |

150

mm |

200

mm |

250

mm |

300

mm |

| L |

305 |

368 |

419 |

470 |

546 |

673 |

705 |

832 |

991 |

1130 |

| D |

177.8 |

215.9 |

244.5 |

266.7 |

311.1 |

374,6 |

393.7 |

482.6 |

584.2 |

673.1 |

| T |

31.7 |

38.1 |

41.3 |

47.6 |

54 |

73.0 |

82.5 |

92.1 |

107.9 |

123.8 |

| H |

520 |

550 |

605 |

710 |

770 |

780 |

980 |

1140 |

1330 |

1450 |

| H1 |

562 |

608 |

670 |

790 |

872 |

907 |

1127 |

1330 |

1564 |

1778 |

|

| (All dimensions in mm) |

|

|

|

| |